Riding Lawn Mower Won’t Start: No Clicking – How To Fix

It is not unusual for your riding lawn mower to not start right away, it might take a couple of tries before it starts, but no response or a clicking sound when trying to start it indicates a problem. The issue is most likely from the battery or the starter. Other underlying problems could also be responsible for its refusal to start, and this article will outline the possible reasons and how to fix them.

To fix an unresponsive riding mower, check for the battery first. Ensure the connections are tight and the terminals are free of corrosion. The battery likely needs to be charged, some components replaced, or it needs a replacement as a whole. However, other factors apart from the battery can affect the starting of your lawnmower, such as the fuse, the ignition switch, faulty control, and so on. Read on to find out how to identify and fix these issues.

When you turn the ignition keys or press the starter button, the riding mower is expected to start almost immediately. If it does not respond or make any clicking sounds, the first thing to reference is the battery. After checking the battery, then you can proceed to run other diagnostics.

Running Checks On The Battery

Here are the steps to take to test the battery:

- Ensure the ignition is turned off.

- Using a multimeter, check the voltage of the battery. If it reads 12V or more, it is okay. Anything less than 12.7V is a sign of a weak or drained battery. To use a multimeter, place the red probe on the positive terminal and the black probe on the negative terminal, and note the reading.

- Corrosion makes the battery not function properly. Use a battery spray cleaner or a DIY mixture of baking soda and water with a metal brush to scrub off the debris to get rid of corrosion. Check the terminals for any sign of corrosion. Coat the terminals in anti-rust grease or petroleum jelly to prevent future corrosion.

- Check the battery casing for swelling or any cracks.

- The connections on the battery may be loose. Check them, and tighten them where necessary.

More Checks

If the battery is in good condition, yet the lawnmower does not start, it could result from the other faulty parts.

- Faulty Solenoid

- Control switch

- Loose motor mounting bolts

- Damaged capacitor

- Faulty circuit (fuse, blade switch, brake switch, ignition switch)

- Others

Faulty Solenoid

The starter solenoid is located on the mower frame inside the starter motor. It works hand in hand with the ignition, receiving electric charge from the battery when the lawnmower is started to carry a more significant amount of current to the starter motor. Therefore, a faulty solenoid can be why your lawn mower won’t click or start.

How To Fix:

- Test the solenoid by using a multimeter. Set the reading to Ohms, and connect the end of the solenoid wire that attaches to the starter motor. The reading for a good solenoid is between 0 to 15 ohms. However, if it reads nothing or infinity, the solenoid is bad and needs to be changed.

Check The Control Module

The control module is a circuit that has the resistors, relays, and the ground side that gets a signal from the safety switch. The circuit module sends a command to the starter through the starter solenoid. There are two methods to test the circuit:

- Wiggle test

Wiggle or shake the wires connected to it, then start the mower. Observe any problems and check the circuit for any loose connection and water.

- Main fuse check:

The fuse keeps the wiring from a short circuit and high current. A blown fuse will hinder the power supply from the battery. To check the fuse, lose the zip tie and remove it from its holder. Check with a multimeter. It will either read around zero ohms or infinity. Infinite resistance shows that the fuse is blown and needs to be replaced.

Loose Motor Mount Bolts

Loose bolts on the motor mounting can hinder the flywheel from making contact with the starter motor. The bolt can also be loose due to a broken lock washer. A lock washer is used to prevent the starter bolt from loosening. If the lock washer is broken, it can easily be replaced with a new one. A good way to keep the flywheel in contact with the starter motor is to change the position of the starter motor. Install the starter motor on top of the flywheel- this reduces its tendency to shift out of place due to vibration during operation.

Damaged Capacitor

A leaky capacitor might be the reason for its refusal to start. You can find the capacitor in the engine with wires connecting to it from the starter motor. It is small in size but relatively larger than a computer chip. A bad capacitor needs to be urgently replaced because it can heat up high and pose a fire hazard.

The solution to a bad capacitor is to replace it with a new one.

Blown Fuse

It is easy to identify a blown fuse by observing it. To reach the fuse, you have to get the battery and battery box out of the way. It is located right beside the starter solenoid. Move the zip tie and pull the fuse. If it appears broken, then it is most likely blown. You can also test using a multimeter. A good fuse should give a reading of around zero ohms. Otherwise, an infinite reading shows that it is blown and needs to be replaced.

Ignition Switch

To test the ignition switch, you also need a multimeter to measure resistance. Connect the multimeter to the ignition switch and start the lawnmower to view the reading. If it measures infinite resistance, then the ignition switch is bad and needs a replacement.

Brake Switch

To access the brake switch, remove the mower’s hood and pull off the air duct after removing the screws. Gently move the fuel tank out of the way and pull off the lower dash. Remove the wire harness of the brake switch and note the white wires. The white wires connect to prongs which will be used on the multimeter to test for resistance.

To test the resistance, touch the meter probes to one prong each and observe the reading. If it reads infinite resistance, then the brake switch is faulty and needs to be changed.

Blade Switch

The process of testing the blade switch is very similar to that of the brake switch. Pull the clutch lever assembly down and disconnect the wire harness to the blade switch. Use the multimeter probes to touch each of the prongs, and read the display. As the previous tests have shown, infinite resistance indicates a bad blade switch that needs to be replaced with a new one.

Other Factors

Suppose all these checks do not show the problem. In that case, other components of the lawnmower may be responsible for the problem- wearied motor brushes, faulty safety switches, loose wiring, the effect of poor maintenance over time, etc. You can also consult your manufacturer’s manual for tips or call an expert to help diagnose and fix the issue.

FAQs

What does a starter solenoid do?

A solenoid is a magnetic device in the starter motor that closes the switch to transmit a larger amount of current to the motor, making it rotate and engage the teeth of the flywheel. It is an electromagnetic switch that works when you turn on the ignition, sending current to the starter.

When do I need to change my lawnmower?

Lawnmowers can last up to ten or fifteen years. They are durable and last longer since they are not used daily. However, the mower might need to be replaced even earlier in some cases. Asides from life span, some signs that indicate you need a new mower include; transmission problems (they are expensive to fix, it is as good as buying a new mower), regular engine problems requiring frequent repairs, too many breakdowns in a short time, crankshaft damage, personal reasons like needing an upgrade.

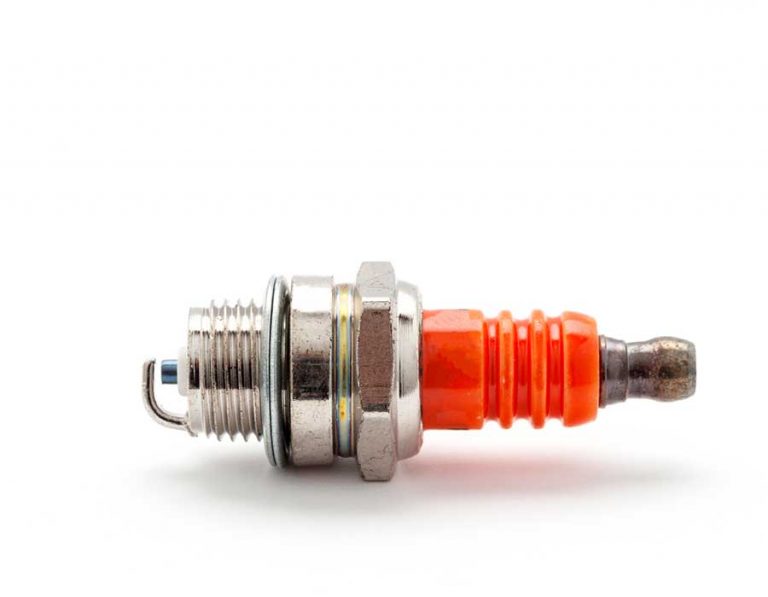

What if the mower dies as soon as it starts?

If your lawnmower kicks off at all but suddenly goes off, it could be traced to the carburetor or spark plug. Inspect both components, check the carburetor for clogging, and clean it with carburetor spray if so. If the spark plug is faulty or broken, then you should replace it with a new one. Make sure to check the carburetor and spark plug only when the engine is off and has cooled for a bit.

Final Thoughts

Identifying the cause of a lawnmower being unresponsive can be tasking, especially if the battery seems to be working fine. These checks are important as you can prevent future issues by observing other components you had ignored. After doing all the checks recommended in this article, it is also advised to involve an expert if the problem is not identified.